UK Industrial Fusion Solutions Ltd (UKIFS) have signed a second-phase collaboration agreement with Seoul National University (SNU) and PowerNix Co. Ltd, to advance continuous-length high-temperature superconducting (HTS) cable technology for nuclear fusion systems.

This collaboration is part of the UK’s national STEP Fusion programme, which aims to build a prototype fusion energy plant, targeting 2040, as well as a path to commercial viability of fusion. In the programme’s first phase (2019–2025), £220 million (approximately KRW 390 billion) has been invested to develop the conceptual design of an HTS-based prototype power plant in West Burton, Nottinghamshire. From June 2024 to March 2025, UKIFS, SNU and PowerNix Co. Ltd carried out a £1 million (KRW 1.8 billion) joint project to co-develop high-current HTS cables – key components in compact fusion systems.

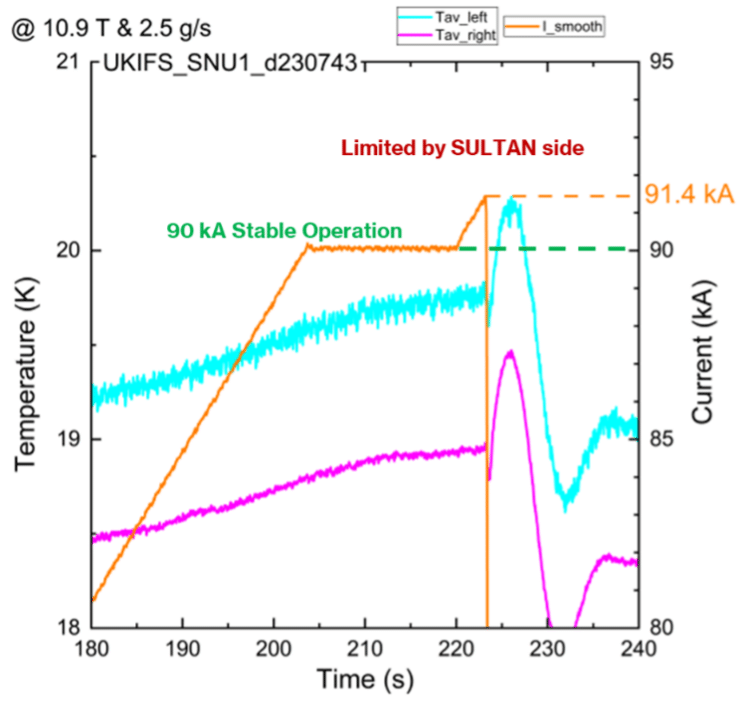

This project delivered a dual 3.6-meter high-current HTS cable prototype for STEP Fusion’s toroidal field magnet system. In July 2025, the cable was tested at the SULTAN facility at EPFL in Switzerland, one of the world’s leading centres for superconducting cable testing, where it demonstrated exceptional performance. It succeeded in reaching the facility’s operating current limit, 91 kA in a 10.9 T background magnetic field, while withstanding electromagnetic forces of around 100 tonnes per metre. It also withstood over 1,400 current ramping cycles under this load at a STEP magnet operating temperature of 20 K, and it survived multiple intentional quenches. Throughout the test campaign, the cable achieved record performance whilst degradation was within the measurement error margin – an unprecedented achievement in the facility’s history of HTS cable characterisation.

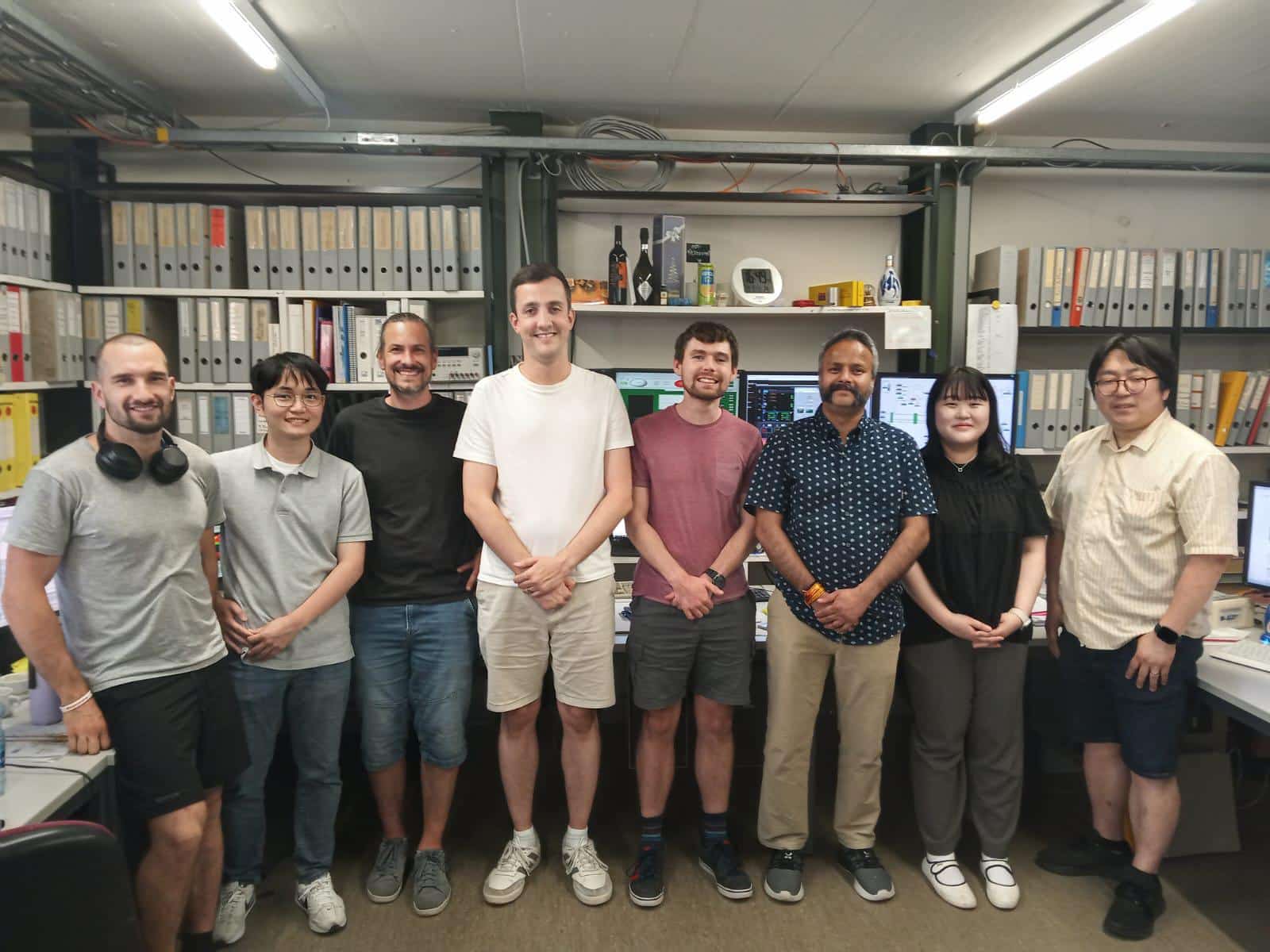

Above: Team members from SNU (Dr. J. Kim and Mr. D. Lee, left), Dr. S. Chouhan from UKIFS, and Dr. J. Greenwood (SULTAN test engineer, far right) at the SULTAN test facility prior to the commencement of testing

These results matched predictions made by cable simulation software developed in-house by the SNU research team, confirming both the accuracy and the maturity of the tools. This success was supported by the PRISM (Program for Research in Innovation of Superconducting Magnets) initiative funded by the Ministry of Science and Information and Communication Technology (ICT) through the National Research Foundation of Korea. The program aims to systematically categorise HTS magnet designs and technologies and develop core innovations for industrial-scale applications including high current HTS cable for fusion machines. The PRISM-affiliated company, Standard Magnet Inc., worked alongside SNU as a subcontractor on this project, contributing to the design, fabrication, and testing of the prototype.

Following the success of the first phase, UKIFS, SNU and PowerNix Co. Ltd signed a second-phase agreement worth £3.6 million (KRW 6.4 billion), running from July 2025 to March 2027. The project will focus on the development and manufacturing of long-length high-temperature superconducting (HTS) cables for commercial applications, including the design and implementation of continuous-production equipment and the construction of cryogenic testing infrastructure.

The partnership will also expand to include the design, fabrication, and evaluation of prototype toroidal field (TF) HTS magnets – key components of future fusion power plant. These efforts are expected to strengthen UK-Korea collaboration in compact fusion research and accelerate progress toward commercially viable fusion energy.

Left: Cable preparation and liquid nitrogen testing prior to shipment to the SULTAN facility. (Right) Measured current data showing the cable reaching the maximum current limit of the SULTAN test facility