Engineers building the UK’s future fusion power plant have successfully tested a key new technology that could make fusion energy cheaper and easier to run.

STEP (Spherical Tokamak for Energy Production) Fusion is developing a prototype fusion plant at West Burton in Nottinghamshire, with the ambition of generating electricity for the grid in the 2040s.

Fusion power relies on extremely powerful magnets to hold super-hot fuel (gas) in place long enough for fusion to occur. For fusion to become a commercially viable energy source, magnets must not only perform at the highest levels but also be maintainable over decades of operation.

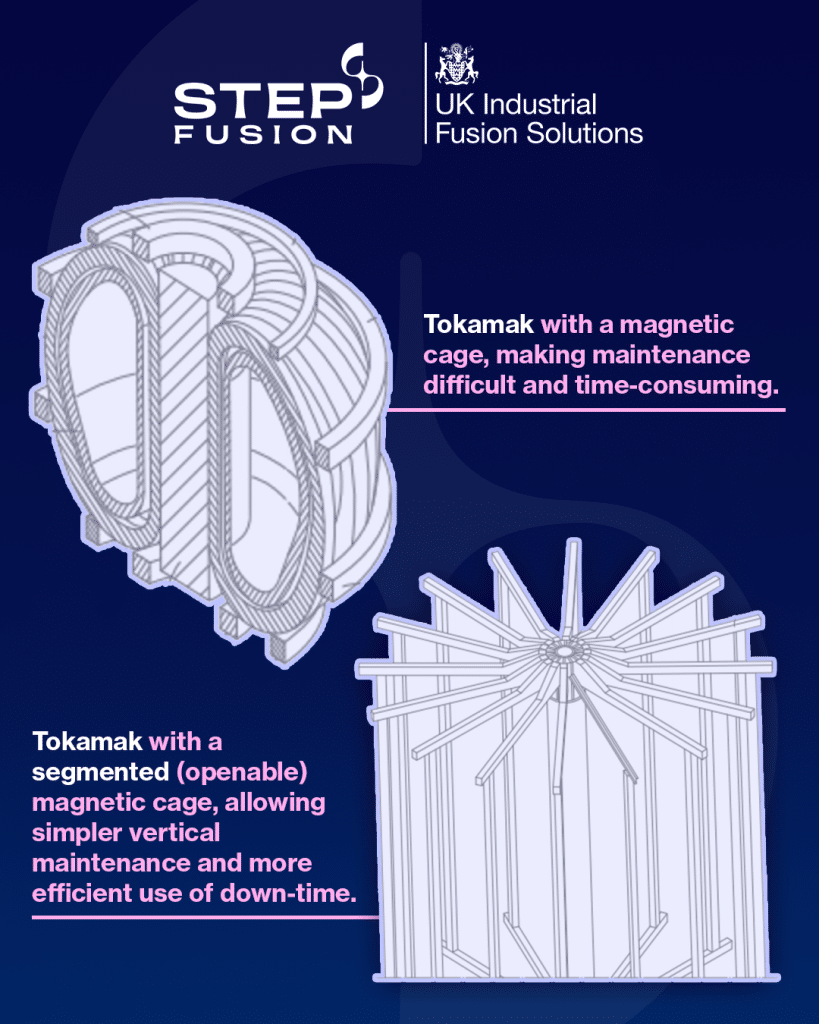

Traditionally, fusion magnets are built as solid, permanent structures, which makes repairs slow, complex and expensive.

STEP engineers are taking a different approach by developing magnets with remountable joints (RMJs) – precision connections that allow sections of a magnet to be taken apart and reassembled for maintenance, much like industrial‑scale plug‑and‑socket connectors.

This allows faster maintenance schedules, shorter shutdowns and lower costs over the lifetime of the power plant, demonstrating the future commercial viability of fusion.

New design and UK innovation

The STEP magnets team has developed and tested a new RMJ design, alongside a novel mechanical clamping system that holds joints together under the extreme forces generated during operation.

The system uses a bladder-based clamp: a sealed bladder containing a liquid that expands as it freezes during cool-down, helping to apply an even contact pressure across the electrical interface at cryogenic temperatures.

The clamping system is now being prepared for patenting, with a view to adoption in future fusion power‑plant designs beyond STEP.

Manufacturing studies have also shown that the joints can be produced using several different industrial techniques, helping to de‑risk future large‑scale production and supply‑chain development in the UK.

Further testing is under way in the UK to examine how multiple joints perform together in realistic, fusion‑specific magnetic environments, bringing the technology closer to deployment in a full power‑plant setting.

Why it matters

Remountable magnet technology could transform how fusion power stations are designed, built and operated by:

- Enabling faster, more targeted maintenance

- Reducing plant downtime and improving availability

- Lowering operating and lifetime costs

- Supporting compact, high‑performance magnet systems suitable for commercial power plants

Aurobindo Siddarth Swaminathan, Principal Engineer for magnets at STEP Fusion, said:

“The ongoing realisation of STEP’s RMJ technology is a multi-million-pound project. But what’s notable is we’ve gone from a concept sketch to delivering and shipping a product for testing in one financial year.

“This has only been possible through successful collaboration with industry partners, the UK Atomic Energy Authority (UKAEA) as fusion partner, and UK Industrial Fusion Solutions (UKIFS) – bringing their combined expertise to the STEP programme.”

By proving that magnets can be both powerful and maintainable, STEP is tackling one of the key barriers to turning fusion from an experiment into a reliable source of clean energy – and strengthening the UK’s position as a global leader in fusion engineering.